MARINE EXHAUST GENERAL:

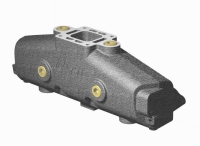

When the time comes to replace your manifolds, the easiest way to insure getting the proper parts for the job is to take a look at your current exhaust system and write down the casting numbers which are on each part. In some cases the number is on the engine side of the manifold and may be hard to see prior to removal. Some manifolds may have no number at all, making it difficult, but not impossible to identify. This is where model number information is handy. Try and find your engine manufacturer and then match up to the model number information to that. In many instances your motor may be several years older than the boat. The installer, whether a hired mechanic or the boat owner, must be aware of the importance of proper gasket installation at the riser to manifold surface. Water leakage at this point is virtually always a gasket seal problem, not a defective part (however, water leakage at an improperly installed gasket will eventually damage the iron parts in addition to allowing water into the engine). Please read our tech tips for installation of gaskets further down the page. Understanding the plumbing of a manifold may help in the installation and reassembly of your manifolds and risers. Familiarize yourself with the OEM service manual and make sketches or photographs of your plumbing system prior to disassembly. This may avoid problems with the installation. Remember to drain water from your manifolds and risers prior to removal of any of the pieces. Failure to drain the parts can result in damage to your engine due to water ingestion. Do not alter or modify gaskets. Order the correct parts for your installation.

MARINE EXHAUST PAINT:

Performance Product Technologies offers the industries only Ceramic Coated direct replacement marine exhaust system products. While other companies offer products with only primer or standard epoxy paint, PPT offers select products with corrosion resistant coatings and ALL of your required mounting hardware. The benefits of a ceramic coated product are that the coating will offer itself to corrosion before allowing any of the substrate material to degrade. There is no such thing as a totally corrosion resistant coating in that all coating are permeable to some degree and therefore will allow water to get behind the coating at some point down the road.

MARINE EXHAUST GASKETS:

The installer should make sure there are no major deformities or obstructions on the gasket surfaces before assembly of manifolds, risers, and elbows. However paint removal is not required.

MARINE EXHAUST BOLTS & TORQUE:

Do not use stainless steel or grade 2 bolts to install the risers or elbows. These bolts are too soft and will not hold a torque setting, which can cause leaks at the gasket surface. Bolt torque should be reset after initial startup, while the engine is still warm. Refer to your original manufacturer's engine service manual for specific torque settings. As a rule of thumb we suggest between 30 - 40 Lb-Ft for 3/8 fasteners threading into cast iron and 20 - 25 Lb-Ft for 3/8 fasteners threading into Aluminum. HOWEVER THE MOST IMPORTANT THING TO REMEMBER WHEN TORQUING MARINE EXHAUST PRODUCTS IS TO PERFORM IN A UNIFORM PATTERN IN ABOUT 2-3 SEPARATE SEQUENCES. 1) 10 LB-FT FOLLOWED BY GOING ON UP TO 15 - 25 LB-FT THEN FOLLOWED BY TAKING THE TORQUE UP TO THE FINAL RATING. THE TORQUE SHOULD THEN BE CHECKED AFTER RUNNING THE ENGINE FOR 30 MINUTES THEN AGAIN AFTER 20 HOURS. Never use anti-seize type products on bolts or studs as this can allow for loosening of the parts.

Studs: To prevent studs from backing out and causing leaks which can cause engine damage, use red thread locking compound. Follow the manufacturers recommendations for their installation and removal. Do not use anti-sieze on bolts or studs as it is a lubricant and will cause fastener to back out.

MARINE EXHAUST PIPE PLUGS AND FITTINGS:

When installing pipe fittings or pipe plugs care must be taken to avoid over-tightening. Pipe plugs and fittings are tapered and an overly tight pipe plug or fitting can crack the casting. Do not use thread sealants which contain Teflon. Do not try to screw the plugs in flush with the casting, they only need to be snug.

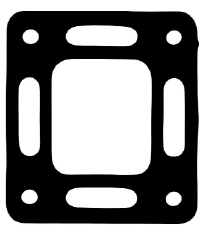

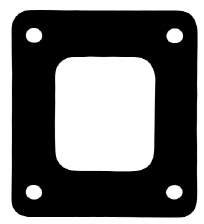

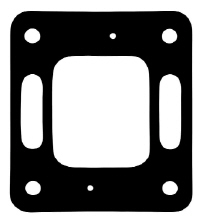

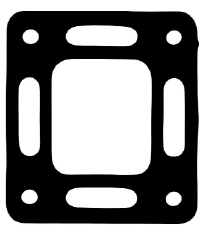

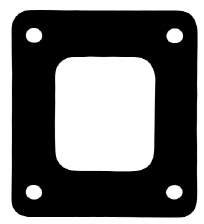

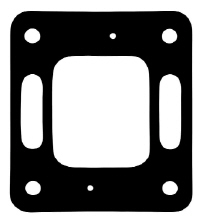

MARINE EXHAUST GASKET PLACEMENT: In some applications the riser gasket alignment is critical. Improper installation of the gasket can cause the engine to have an overheating concern. The following is a list of these gaskets and how they should be aligned:

4 Slot open style gasket used in Mercruiser application during the mid-90's and allows for full coolant flow from the manifold into the riser. This gasket is typical to what is used on cold manifold style exhaust/cooling systems. To read more about warm versus cold manifold systems, select this link.

Closed gasket used in Fresh Water Cooling applications. This gasket is used to contain the anti-freeze in the exhaust manifolds along with FULL Fresh Water Cooling systems. To read more about 1/2 versus full closed cooling systems, select this link.

Restrictor gasket used in Mercruiser applications during the 80's and early 90's. This gasket is used with "warm manifold" style raw water cooling systems. To read more about warm versus cold manifold systems, select this link.

Marine Exhaust - KEEL COOLING: Keel Cooling is often installed incorrectly and can cause manifolds to crack internally from excessive heat. Do not install manifolds into keel cooled systems that rely solely on the circulator pump with small diameter pipe for its circulation. This is not satisfactory and will overheat the manifold.

|